Since

graduating from the University of

York in the UK with a B Eng (Hons) in Electronic Engineering,

James McLeod has spent most of his working life involved with Intergrated

Circuits (ICs or "Silicon Chips") and semiconductors in general.

This began even before his university

course started, when James McLeod had a summer placement job as a student.

He was given a project to write a software tool that could simulate the

test vectors used by a Schlumberger Sentry Series

20 ATE system and display them as a graphical waveform on a

monitor, rather than the 0s and 1s that the test engineers usually had

to work with. The results were so useful that the software was developed

further as the third year project for his Electronic Engineering degree,

so that the final program was able to understand not only the test vectors

but the compiled test software programs that used them too. Test engineers

could therefore carry out much of their program and development and debugging

off-line, using standard computers, rather than spending large amounts

of time on the ATE system, with its very basic editor and debug tools.

After completing his degree, James McLeod

went back to work on the Sentry Series 20, and wrote ATE software on the

system to test and characterise various different digital ICs. He also

developed the simulator software further, including converting the entire

sortware suite from VAX Pascal on VT340 Colour Graphics Terminals running

VAX/VMS to Turbo Pascal on Elonex 368SX PCs running Windows 3.0.

After a few years James McLeod finally

ended up running the laboratory, and as time went by the team acquired

more types of specialist equipment for characterising ICs, and the type

of work gradually became more varied.

The first major acquisition was an EBeam

prober system called an IDS 4000, which was replaced shortly afterwards

by a more sophisticated version, the IDS

5000HX. These systems were produced by Schlumberger and

in the early 1990s they revolutionised the debug process for new IC designs.

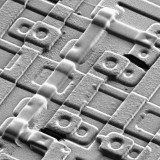

In simple terms, they are a low power (1keV) Scanning Electron Microscope

(SEM) which is able to image a device while it is operating, and acquire

a waveform from a signal track on the device by sampling the image information

at a given location. The software environment is simple and intuitive

for engineers to use, since the SEM image has an Oscilloscoe probe icon

which can be moved to the point of interest, and the waveforms acquired

are displayed on the screen as a virtual Oscilloscope tool. This allows

design engineers to look at the signals within their device and check

that the operation is as expected from their CAD simulation, and Failure

Analysis engineers can compare signals from Good and Bad devices to find

the location of a device failure. Although this had been possible in the

past, using mechanical microprobes, this is a slow and tedious process

with a significant risk of damage to the device from the probe needles.

The EBeam systems by comparison were a much better solution : waveforms

can be acquired from any visible signal track, with a resolution of better

than 1um, and because the process is completely contactless there is no

risk of damage to the device and the operation of the circuit is not affected

by the probing.

Once a design problem has been found,

the next logical step in the process is try out a possible fix to the

circuit to see if the correct operation can be achieved. Schlumberger

therefore developed a new product called the IDS

P2X. This is a Focussed Ion Beam (FIB) system, which uses

a beam of Gallium Ions and various different chemical gases to selectively

etch or deposit insulator or conductor. This provides the basic functionality

to be able to implement design fixes on the IC itself, by cutting and

reconnecting signal tracks, with resolutions of better than 1um. When

used in conjunction with an EBeam system, the two tools are a powerful

combination. A design problem can be identified on the EBeam, a prototype

fix can then be implemented on the FIB, and the modified device can be

put back in the EBeam to assess whether the fix has been successful.

The team acquired an IDS P2X system a

few years after the IDS 5000 HX, and these two systems have proved to

be invaluable in many aspects of their work. The FIB is an especially

versatile and useful tool, and has been used for almost ten years now

to assist dozens of semiconductor companies in resolving design problems

with their new devices. The IDS P2X only has a nominal minimum resolution

of 50nm, but so far James McLeod has been able to successfully carry out

FIB modifications on Metal 1 on devices with 8 layers of interconnect,

and on process geometries down to 0.13um. Although the IDS P2X was only

ever designed to work with Aluminium processes, he has also been able

to successfully carry out a number of FIBs on devices with Copper processes

too.

Some time later, the Sentry Series 20

tester was replaced by a newer Schlumberger ITS

9000 EXA Mixed Signal IC test system. This provided substantial

improvements in terms of speed, accuracy, and flexibilty across all aspects

of device test and characterisation. The ultra-stable liquid-cooled system

was derived from the ITS 9000 tester architecture originally developed

for Intel to allow comprehensive testing of their 486 and Pentium microprocessors,

which for the first time allowed test engineers the flexibilty to configure

tests with independent voltage and timing set-ups on every device pin

if necessary. The ITS 9000 EXA was the Mixed-Signal tester from this family,

which provided an integrated test solution for Digital, Mixed-Signal,

and Analog devices. It supported 200MHz data rates on up to 448 Digital

test channels, and up to four Analog measurement channels (any combination

of High Accuracy or High Frequency).

During his career, James McLeod has performed

test and design debug work for some of the biggest names in the electronics

industry, including Intel, Sony, Analog Devices, Alcatel, Maxim, Thomson,

and ST, plus dozens of smaller companies from all over the world (although

most of our customers have been based in the UK). If you have a design

debug problem with your latest IC, our EBeam characterisation and/or FIB

circuit edit capability might be able to help. For more information, please

contact James McLeod by email at jamesmcleod@mail2web.com